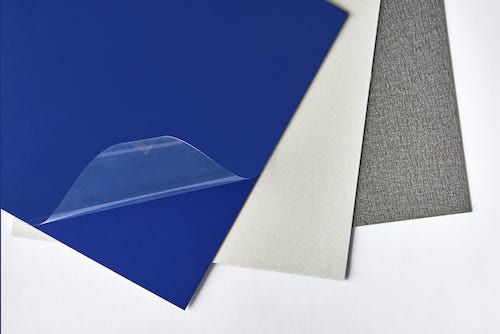

Metal Surfaces

SAMDEX offers a wide range of protective films for metals: aluminium, stainless steel and coated metals, including laser film for cutting metals.

Protective film for metal surfaces is characterised by high durability due to resistance to exterior conditions like moisture, UV radiation and sub-zero temperatures (protective film for coated metals even up to 12 months and laser film for cutting stainless steel up to 6 months).

Professional products by SAMDEX go with:

- structure and types of protected metal surfaces: smooth, glossy, high gloss, silver, coarse-grained mat and structural

- all methods of treatment like: moulding, cold-rolling, splitting, cutting, including laser cutting, bending and rolling, continuous and non-continuous extruding

- resistant to carrying, storing, transporting

- conditions of production

Protective films for metal roof sheets and shingles and laser films are distinguished for excellent adherence, which can be easily controlled during all the process of application and storing. Protective films for metal by SAMDEX do not create the effect of ‘blocking’, it means that complete removal is easy, even after foaming. Films for metal protect the surface against the risk of crumpling, burning or chipping. ‘Easy peel’ system vouches for immediate removing the film from the metal protected, without leaving any stains or remains of marking on the surface. Protective films for metal surfaces by SAMDEX are characterised by excellent parameters. Specialists of SAMDEX remain fully ready to help customers pick the most advised product and to match the individual order, for example to insert a print with a logo on the film, or with name of the company or firm, technological data, advertisement or warning.